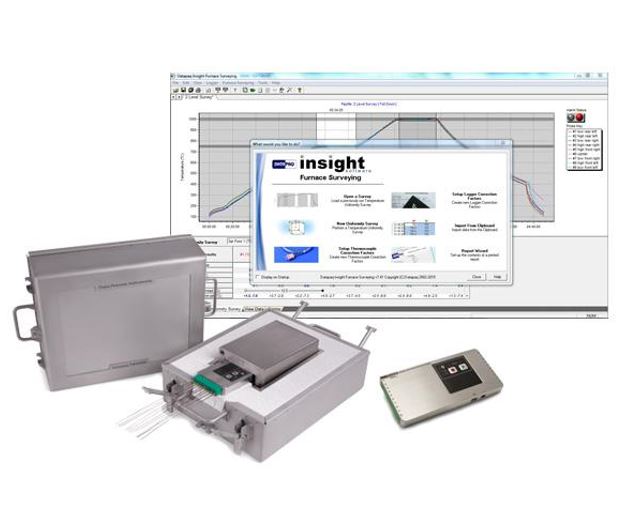

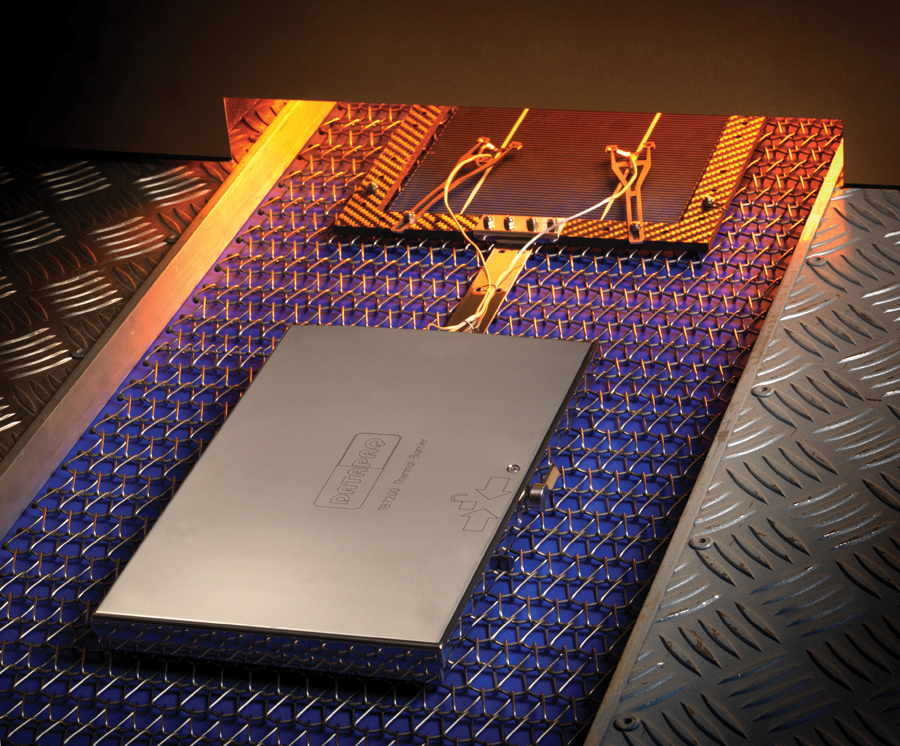

For metal heat treatment industries, measuring both product temperature and its environment is critical to ensure both product quality and process efficiency, which is why Fluke Process Instruments has designed the most robust, sophisticated furnace profiling systems.

Read more

The Datapaq Oven Tracker Systems from Fluke Process Instruments are designed to provide comprehensive thermal profiles for applications such as powder coating, paint curing, component supply and general paint, powder and e-coat OEM applications up to 400°C.

Datapaq Kiln Tracker Systems from Fluke Process Instruments are designed to provide thermal profiles for ceramic-firing applications in roller hearth kilns, hydro kilns, clay block kilns and tunnel kilns. Each system uses our intuitive Insight™ software to enable you with real-time monitoring.

Read more

Designed to measure and log true product and environmental temperatures and to deliver reliable, accurate HACCP process validation, the Datapaq Food Tracker System is the ideal solution for demanding food processing applications.

The system is particularly suited to poultry, meat and seafood processing.

Read more

Monitor the temperatures for every soldering application – including wave, reflow, vapor phase, selective and rework stations – in real-time with the Datapaq Reflow Tracker System.

This solution is ideal for electronics manufacturing and semiconductor applications.

Read more

The SolarPaq Thermal Profiling Systems from Fluke Process Instruments are designed specifically for solar photovoltaic (PV) manufacturing including applications like contact firing, contact drying, anti-reflection coating for the solar cell, lamination and other thin film processes.

Fluke Process Instruments is a division of Fluke Corporation with over 150 years of combined industrial experience, we've pioneered a solution specifically for your process needs. Three industry leaders Raytek, Ircon, and Datapaq, joined together to create Fluke Process Instruments, offering a broad portfolio of industrial temperature measurement solutions. Providing non-contact infrared temperature measurement and thermal profiling solutions and thermal profile equipment is our business.