About Fluke Acoustic Imagers

Fluke acoustic imagers are versatile tools that address various industrial needs. They empower you to prioritize repairs, enhance safety, and save costs, whether you're detecting air, steam, gas, or vacuum leaks in compressed air systems, identifying partial discharge, or detecting bearing faults in conveyor systems.

The All-in-One Tool You Have Been Looking for to Visualize Leaks, Partial Discharge, and Mechanical Issues

The ii915, ii905, and ii500 models revolutionize industrial inspections by visualizing sound. These Fluke tools enhance efficiency, uptime, and safety while reducing costs through swift inspections of air/gas leaks, electrical discharges, and mechanical issues.

|

|

|

|

ii500 |

ii905 |

ii915 |

|

| Applications | ii500 | ii905 | ii915 |

| LeakQ™ | Scale (1-10) | Leak size scale, leak rate, and leak cost estimation | Leak size scale, leak rate, and leak cost estimation |

| PDQ Mode™ | • | ||

| MecQ™ | • | ||

| Features | |||

| WiFi | • | • | |

| Frequency | 2 to 52 kHz | 2 to 65 kHz | 2 to 100 kHz |

| Detection range | Up to 50 m (164 ft)* | Up to 70 m (230 ft)* | Up to 120 meters (393 ft)* |

| Resolution | 0.3 MP | 5.0 MP | 5.0 MP |

| Battery life | 6 hours | 6 hours | 6 hours |

| Tripod connector | • | • | |

| Memory | 20GB (>5000 pictures / > 999 videos) | 32GB (>8000 pictures / > 1600 videos) | 32GB (>8000 pictures / > 1600 videos) |

*Depending on ambient conditions

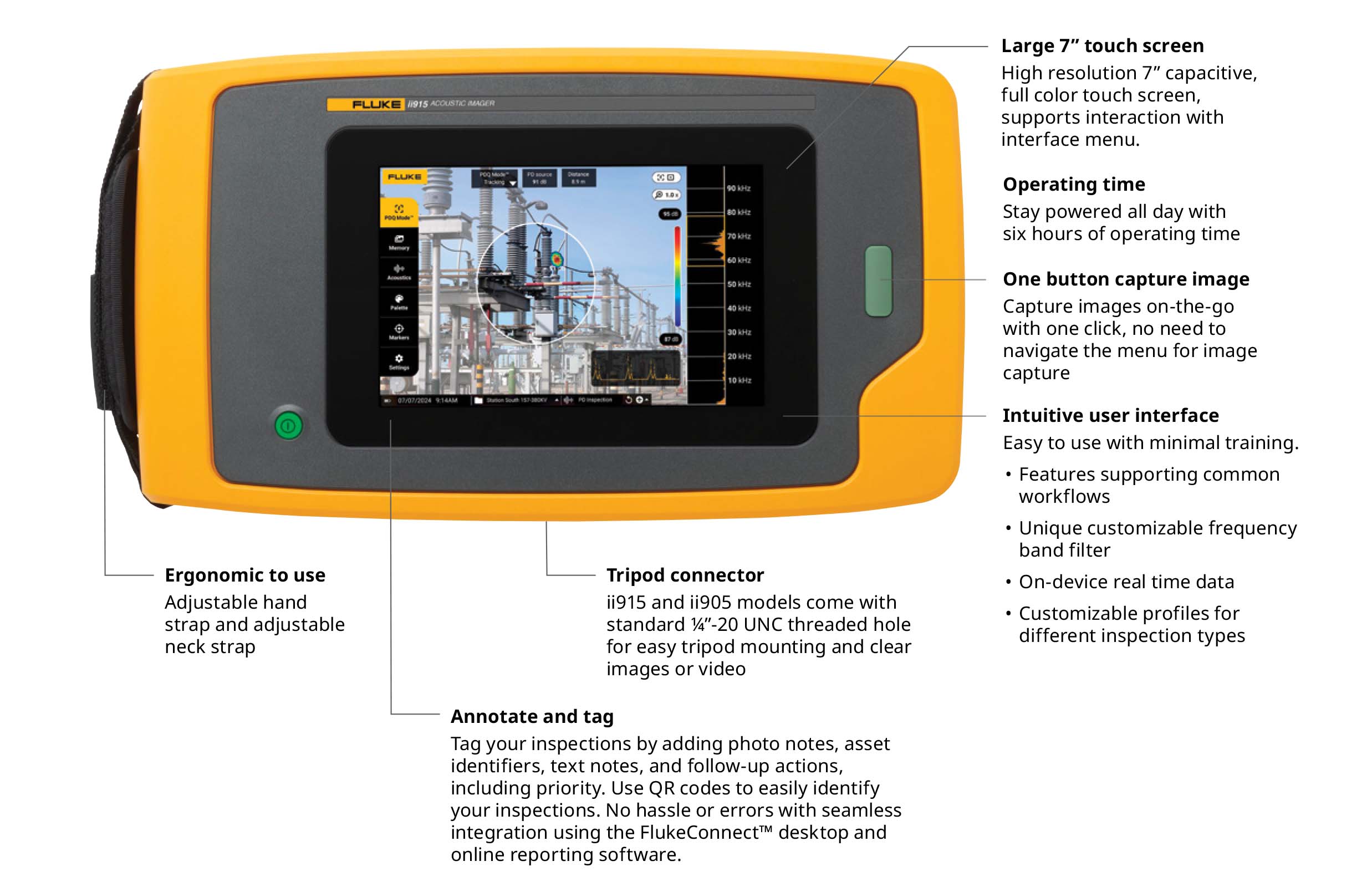

Quick, Easy, and Intuitive User Interface

Three Applications for Acoustic Imaging

Leak Detection

The Fluke ii Series acoustic imagers simplify leak detection in compressed air, gas, steam, and vacuum systems. Maintenance technicians can check for leaks during routine tasks, even during peak operation hours. The imagers visualize sound, creating a SoundMap™ superimposed on a visual image for efficient detection of compressed gas leaks.

Download Data Sheet

Partial Discharge

The Fluke ii915 Acoustic Imager with PDQ Mode™ translates partial discharge sounds into visuals, pinpointing their location. Its extended frequency range (2-100 kHz) aids early detection, allowing proactive maintenance and prevention of catastrophic events.

Review Specifications

Mechanical Inspection

The Fluke ii915 with MecQ™ revolutionizes conveyor system maintenance. It efficiently scans large areas, detecting and documenting potential issues early. Contactless scanning and advanced noise filtering ensure safety and clear images, surpassing traditional methods.

Explore Technical Data

Fluke Premium Care Eligible

When you invest in your Fluke test tools, you want your money to go as far as possible. Fluke Premium Care is a paid offering that provides coverage above and beyond the original product warranty, so you don’t need to worry about unexpected downtime caused by damaged test equipment, accessories, or tools in need of calibration or repair.

All Fluke Acoustic Imagers are Fluke Premium Care eligible, subject to availability.