Finding Compressed Air Leaks Has Never Been Easier, Even in Noisy Environments

Visualize Leaks From a Safe Distance with the Fluke ii905 Acoustic Imager

Inspect an Entire Plant for Leaks in Just a Few Hours

Transform Your Maintenance with Fluke Acoustic Imaging

Ensure safety and reduce costs with our advanced acoustic cameras. Conduct inspections without close contact, eliminating hazards for your team. Avoid unplanned downtime while achieving significant energy savings. Pinpoint issues efficiently, make predictive maintenance decisions, deploy with ease and free up specialized resources.

Detect, Locate, and Assess Gas Leaks

The Fluke ii905 Acoustic Imager with LeakQ™ technology empowers maintenance teams detect, locate, and assess gas and vacuum leaks efficiently. From compressed air systems to pipelines and industrial equipment, the Fluke ii905 provides valuable insights to optimize operations.

“It takes me all of 30 seconds to a minute to find an air leak with the Fluke Acoustic Imager. Some days we can find and repair 30 or 40 leaks in just a couple hours. Plus, we can use it during production hours, when it’s extremely loud in here and still been able to capture leaks at the rafter level up to 6 to 9 meters (20 to 30 feet) away." - Josh Stockert, Genie, Terex AWP

Monitoring and Detection

The Cost of Leaks

Small leaks in compressed air and gas systems can lead to significant financial losses. Annually, these leaks can cost up to:

$5,611

Cost of 100 1/32-inch leaks at 90 psig

$10,991

Cost of 50 1/16-inch leaks at 90 psig

$38,776

Cost of 10 1/4-inch leaks at 100 psig

Minimize Energy Waste

With the Fluke ii905, you have the power to minimize energy waste in systems with numerous joints and points of connection. Every interface has the potential to become a leak. Our acoustic imager enables you to easily detect and repair them before they lead to equipment degradation or product quality issues.

Boost Efficiency with Easy Deployment

Fluke acoustic cameras simplify vacuum leak detection. No specialized training is required for operation. Equipped with built-in tools, anyone on your team can visualize leaks, document findings, and prioritize repairs, ensuring reliability and optimal performance.

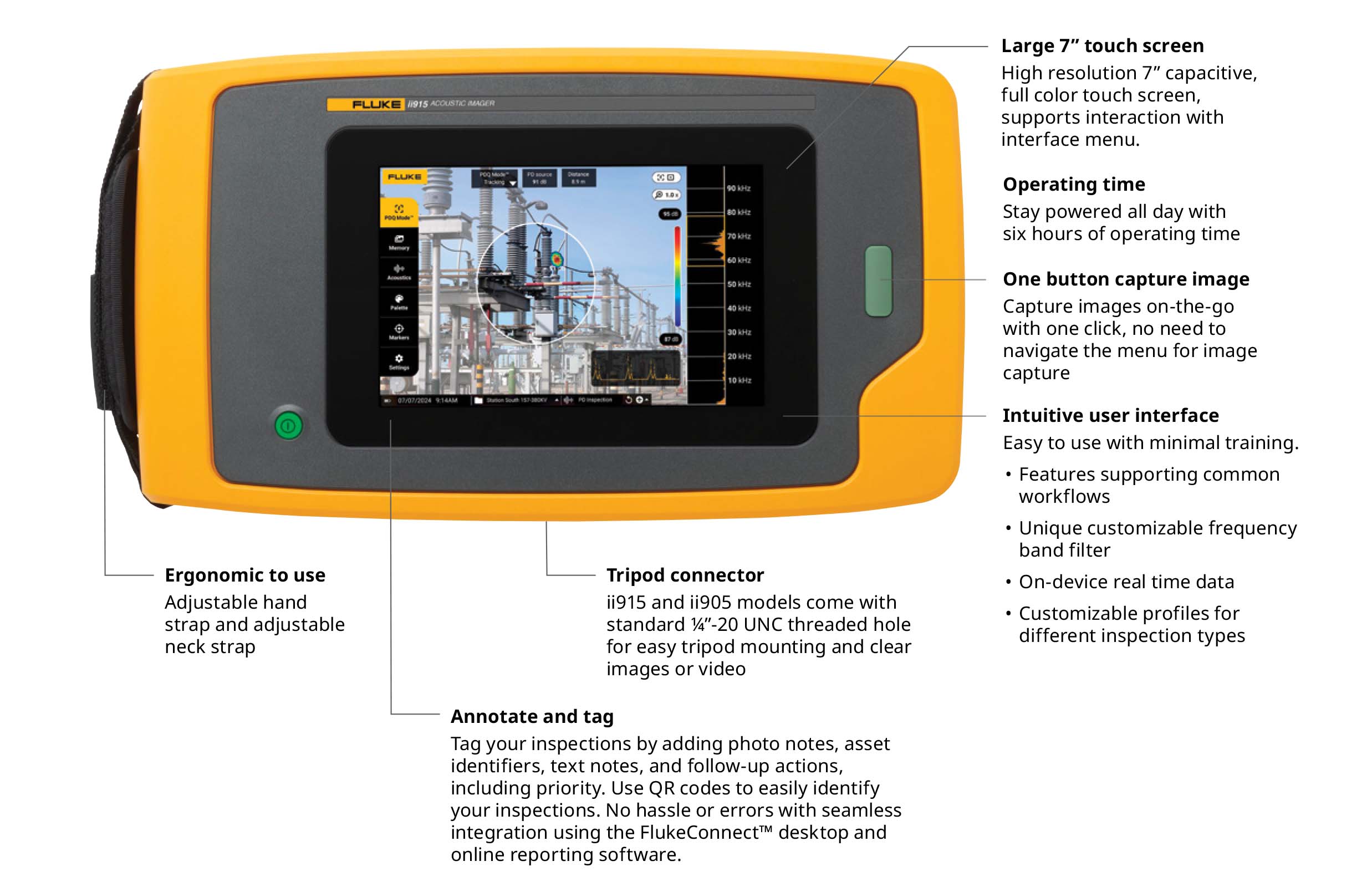

Quick, Easy, and Intuitive User Interface

The Fluke ii Series Acoustic Imagers Make Leak Detection Simple to Learn and Easy to Implement

• Quick Detection: Even users with minimal experience can start detecting leaks within minutes. The tool estimates leak size and cost, incorporating a new distance-estimation feature and the 1-10 LeakQ™ severity index.

• SoundMap™ Overlay: The 7” LCD touchscreen overlays a SoundMap on images for rapid leak location identification.

• Tagging and Organization: Tag and annotate images and videos and organize them in folders for efficient organization.

• Leak Sizing: Prioritize repairs by leak size for maximum impact.

• Collaboration: Share visuals, tags, and notes seamlessly with team members and repair personnel using the reporting tool.

Copyright ©1995 - 2025 Fluke Corporation