Facilities Management (Power)

Switchboard - Power quality

cleanliness of the power can be determined through load study to obtain the power quality condition of the facility. Common key concerns are dips, swells, voltage fluctuations,

harmonics and transients.

The Fluke 1777 Class A Power Quality Analyzer helps you easily analyze the power quality events and perform troubleshooting. It also support energy study to plan for increased

power capacity needs for expansion.

Switchboard - Electrical problem

Electrical problems can be found in the circuit breaker area which can disturb the power that is being distributed to the server. While scanning the components in the power distribution units such as the circuit breaker panel, look at the lugs and terminals for signs of loose contacts and disconnect that can lead to downtime.

Facilities Management (Power)

Uninterruptible Power Supply (UPS) System

There are a couple of components that provide back-up function when utility power supply is down. These back-up power are enabled by batteries, static transfer switch, inverters and grounding.

UPS - Battery

There is no need to disconnect or discharge the backup battery in order to conduct a battery maintenance. The Fluke BT521 Battery Analyzer can measure battery health condition via capturing key parameters such as voltage, internal resistance and temperature of each cell in accordance to IEEE1188 standards.

UPS - Static Transfer Switch

Multiple types of automatic power switches are available to deliver seamless power between power feeds in the downstream of the UPS system. The transfer time can be as fast as

4ms.

Use a field Fluke ScopeMeter for regular preventive maintenance routine to determine the state of the switches– accurately test and measure transfer time on-site.

UPS - Grounding System

Poor grounding not only increases the risk of equipment failure, but it is also dangerous. The fault current needs a safe path to ground. The IEEE have recommended a ground

resistance of less than 5 ohms for grounding and bonding.

The Fluke 1625-2 supports grounding testing within the facility using the innovative stakeless method.

Facilities Management (Power)

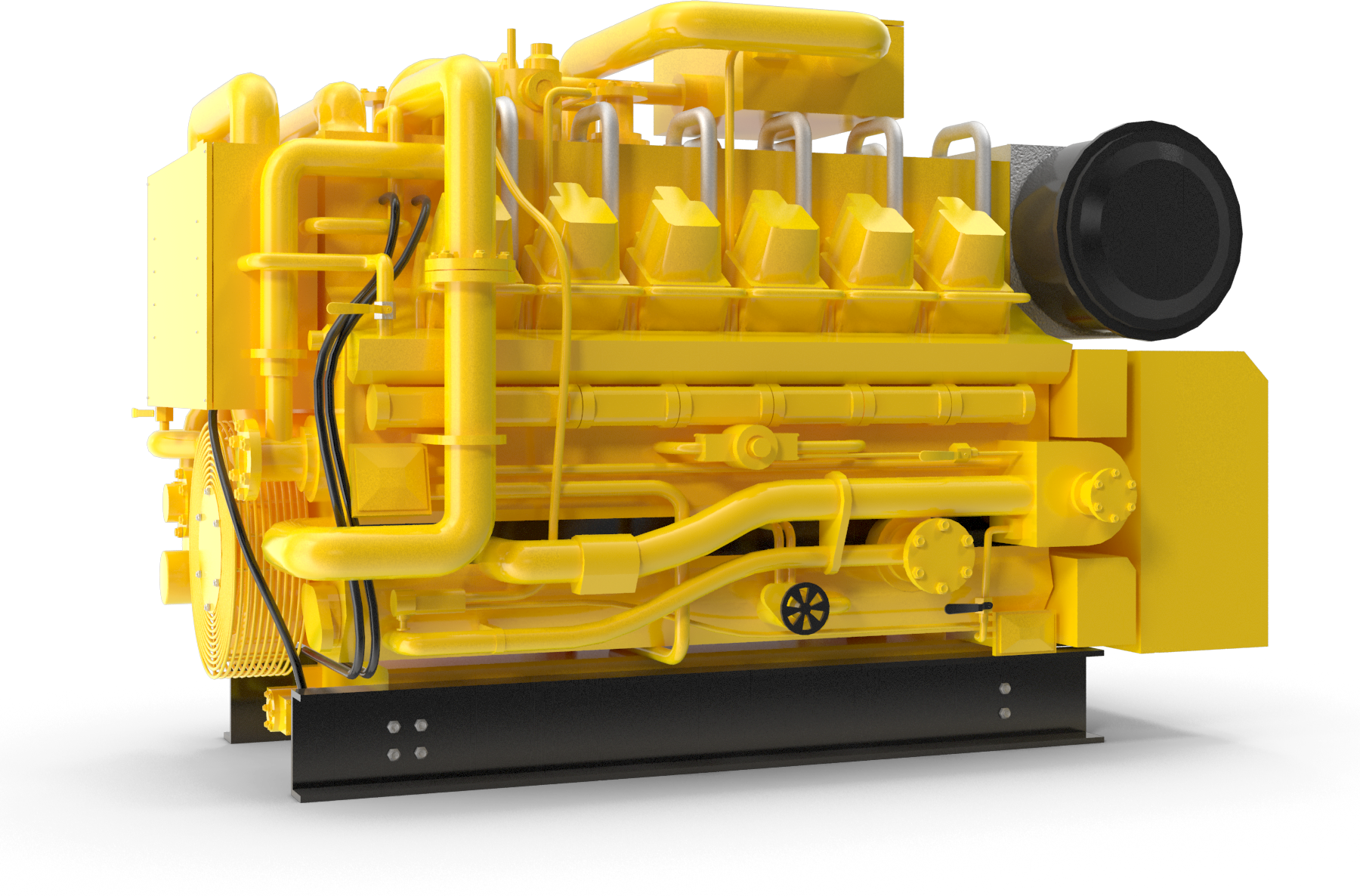

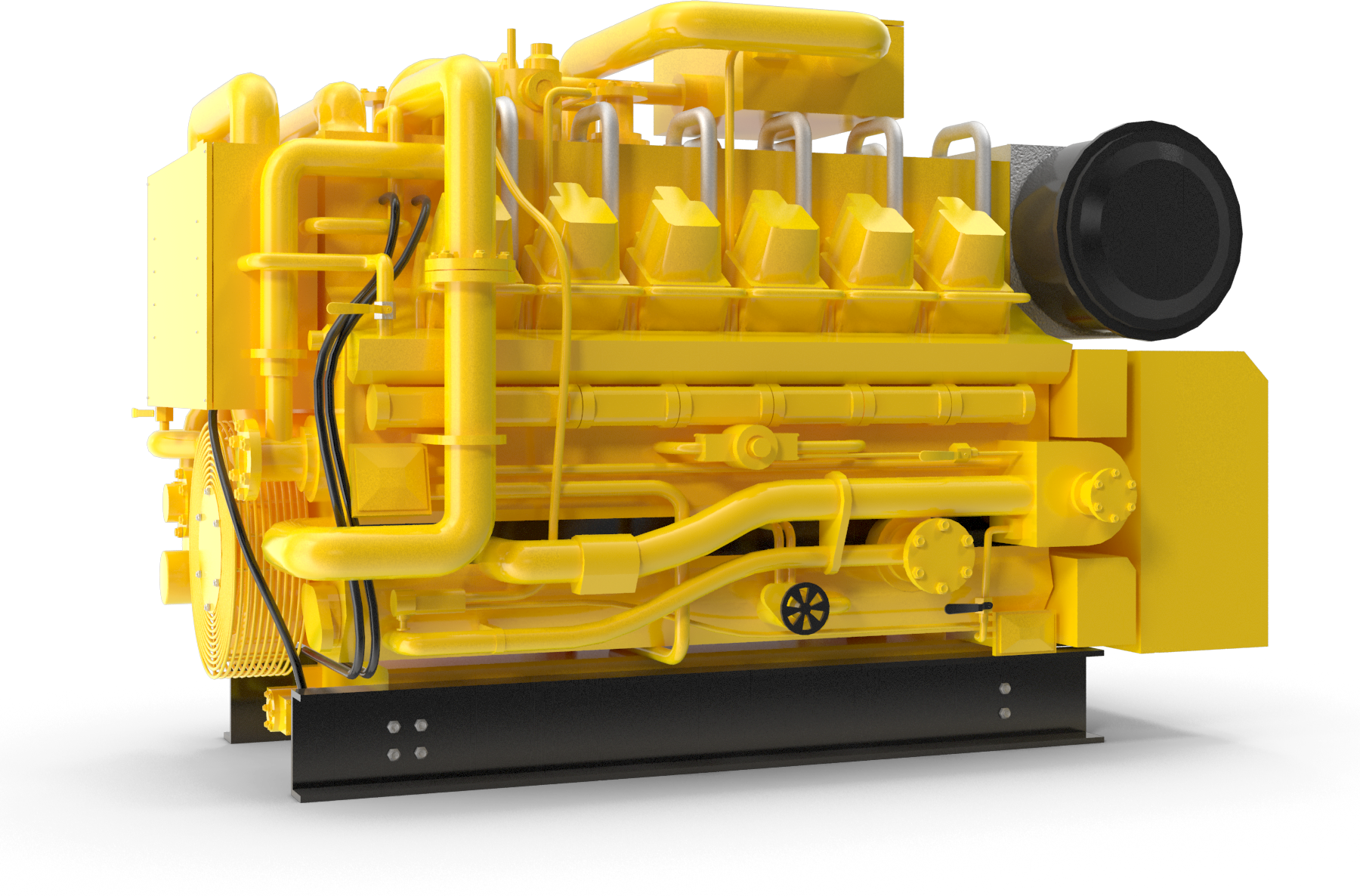

Generators

It is critical to regularly test and maintain backup generators to reduce failure. There are a couple of inspections to eliminate potential failure.

| • | Measure any fluid leaks with the Fluke Thermal Imager to quickly spot leak locations. |

| • | At larger facilities with multiple generators and paralleling switchgear, ensure generators run in-sync (same rpm and in-phase with each other) to avoid downtime. Fluke 190 Series-III ScopeMeter presents the electrical waveform for user to picture the actual performances and ensure it is in phase. |

Facilities Management (Power)

Switchboard - Power quality

The cleanliness of the power can be determined through load study to obtain the power quality condition of the facility. Common key concerns are dips, swells, voltage

fluctuations, harmonics and transients.

The Fluke 1777 Class A Power Quality Analyzer helps you easily analyze the power quality events and perform troubleshooting. It also support energy study to plan for increased

power capacity needs for expansion.

Switchboard - Electrical problem

Electrical problems can be found in the circuit breaker area which can disturb the power that is being distributed to the server. While scanning the components in the power distribution units such as the circuit breaker panel, look at the lugs and terminals for signs of loose contacts and disconnect that can lead to downtime.

Facilities Management (Power)

Uninterruptible Power Supply (UPS) System

There are a couple of components that provide back-up function when utility power supply is down. These back-up power are enabled by batteries, static transfer switch, inverters and grounding.

UPS - Battery

There is no need to disconnect or discharge the backup battery in order to conduct a battery maintenance. The Fluke BT521 Battery Analyzer can measure battery health condition via capturing key parameters such as voltage, internal resistance and temperature of each cell in accordance to IEEE1188 standards.

UPS - Static Transfer Switch

Multiple types of automatic power switches are available to deliver seamless power between power feeds in the downstream of the UPS system. The transfer time can be as fast as

4ms.

Use a field Fluke ScopeMeter for regular preventive maintenance routine to determine the state of the switches– accurately test and measure transfer time on-site.

UPS - Grounding System

Poor grounding not only increases the risk of equipment failure, but it is also dangerous. The fault current needs a safe path to ground. The IEEE have recommended a ground

resistance of less than 5 ohms for grounding and bonding.

The Fluke 1625-2 supports grounding testing within the facility using the innovative stakeless method.

Facilities Management (Power)

Generators

It is critical to regularly test and maintain backup generators to reduce failure. There are a couple of inspections to eliminate potential failure.

| • | Measure any fluid leaks with the Fluke Thermal Imager to quickly spot leak locations. |

| • |

At larger facilities with multiple generators and paralleling switchgear, ensure generators run in-sync (same rpm and in-phase with each other) to avoid downtime. Fluke 190 Series-III ScopeMeter presents the electrical waveform for user to picture the actual performances and ensure it is in phase. |

Facilities Management (Cooling)

Chiller and Cooling Tower

The running flow of water within the heat exchange cycle can face certain issues during process. A failed fan in the cooling tower places strain in the heat exchange process. The temperature of the water in the pipelines can display insulation problem. These problems can be identified with a thermal imager such as the Fluke TiS75+ Thermal Imager.

Motor and Drive

The motor plays an important role in driving both the pump and cooling fan for the HVAC systems. The variable speed drive (VSD) is commonly seen controlling the speed of the

motor to adjust to the load requirement.

These mechanical systems are subjected to mechanical failures. Capture the early signs of problem with the Fluke 810 Vibration Tester. It diagnoses the mechanical problems and

provides the answers to mechanical issues such as bearing, misalignment etc.

Facilities Management (Cooling)

Chiller and Cooling Tower

The running flow of water within the heat exchange cycle can face certain issues during process. A failed fan in the cooling tower places strain in the heat exchange process. The temperature of the water in the pipelines can display insulation problem. These problems can be identified with a thermal imager such as the Fluke TiS75+ Thermal Imager.

Motor and Drive

The motor plays an important role in driving both the pump and cooling fan for the HVAC systems. The variable speed drive (VSD) is commonly seen controlling the speed of the

motor to adjust to the load requirement.

These mechanical systems are subjected to mechanical failures. Capture the early signs of problem with the Fluke 810 Vibration Tester. It diagnoses the mechanical problems and

provides the answers to mechanical issues such as bearing, misalignment etc.

IT/Server Room/Cabling Infrastructure

Server Rack

Thermal imager is useful for monitoring power strips, power supplies built into the racks as well as electrical connections and power strips. Look for overheating due to loose

connections and overload.

A thermal scan can prevent potential equipment failure during daily inspection without stopping operations. Use the Fluke TiS75+ Thermal Imager to pick up these problems with

ease.

Temperature and Humidity

The cooling load in the server room is critical to maintain an ideal environment temperature not exceeding 22 °C to prevent server shut down.

Aside from the temperature, a humid environment can lead to corrosion on electronic equipment. Quickly and conveniently take accurate humidity and temperature readings with the

Fluke 971 Temperature Humidity Meter to verify environment conditions.

Airflow

An important consideration in the design of Data Center is the direction of airflow to reduce the amount of heat generated by concentrated equipment in the server room. Test and

verify cooling effectiveness with the Fluke 922 Airflow Meter.

Besides determining airflow, Fluke 922 can be used to determine positive pressure and air velocity of HVAC systems. Measure differential and static pressure, velocity and

airflow to identify clogged air filters and evaluate efficiency of air handlers and compressors.

Air Particle Sizes

IT facilities typically use the ISO 14644-1 standard to determine for the level of clean air that flows within the IT or Server room. Common contaminants such as electrostatic

dust can affect servers, resulting in data loss and resets.

The Fluke 985 Portable Particle Counter assess air quality easily and accurately by providing an the particle size counts within the area.

Versiv™ CableAnalyzer™

Fluke Networks Versiv™ copper and fiber CableAnalyzer ™ will test and certify network cabling to stringent international standards like TIA-568 and ISO 11801, to ensure networks services will run at the desired Ethernet speed.

Certify the performance of MPO trunks for loss and polarity

MultiFiber Pro Optical Power Meter and Source is the first fiber tester that can certify MPO fiber trunks without the use of fan-out cords. This singlemode and multimode MPO fiber testing kit eliminates the complexity of polarity issues, and it makes cassettes easier to test in the field.

Fiber Inspection

The FI-3000 Autofocus/Autocentering Camera will inspect and certify all fiber connectors end-face to IEC 61300-3-35 test limit with automated pass/fail results in seconds. It can also integrate with Versiv™ Cabling Certification System and LinkWare™ Reporting Software for simple operation and documentation or with mobile phones for testing and sharing.

FiberLert™ Live Fiber Detector

Quickly verify fiber activity, polarity, and connectivity with the FiberLert™ Live Fiber Detector. This pocket-sized tool tests single-mode, multimode, UPC and APC patch cords and ports with a non-contact / non-contaminating detector. The LightBeat™ feature flashes the LED, indicating a powered-on condition and good battery, a timer shuts FiberLert™ off after five minutes of inactivity to extend battery life (2xAAA, included).

Fiber Optic Cleaning Kits

Dirt, dust and other contaminants are the enemies of high-speed data transmission over optical fiber. Fluke Networks’ Fiber Optic Cleaning Kits are lint-free and enable an optimal wet and dry cleaning process with easy-to-use quick clean cleaners, cleaning cube/card and the best optic solvent pen to clean both patch cords and fiber end faces inside ports.

IT/Server Room/Cabling Infrastructure

Server Rack

Thermal imager is useful for monitoring power strips, power supplies built into the racks as well as electrical connections and power strips. Look for overheating due to loose

connections and overload.

A thermal scan can prevent potential equipment failure during daily inspection without stopping operations. Use the Fluke TiS75+ Thermal Imager to pick up these problems with

ease.

Temperature and Humidity

cooling load in the server room is critical to maintain an ideal environment temperature not exceeding 22 °C to prevent server shut down.

Aside from the temperature, a humid environment can lead to corrosion on electronic equipment. Quickly and conveniently take accurate humidity and temperature readings with the

Fluke 971 Temperature Humidity Meter to verify environment conditions.

Airflow

An important consideration in the design of Data Center is the direction of airflow to reduce the amount of heat generated by concentrated equipment in the server room. Test and

verify cooling effectiveness with the Fluke 922 Airflow Meter.

Besides determining airflow, Fluke 922 can be used to determine positive pressure and air velocity of HVAC systems. Measure differential and static pressure, velocity and

airflow to identify clogged air filters and evaluate efficiency of air handlers and compressors.

Air Particle Sizes

IT facilities typically use the ISO 14644-1 standard to determine for the level of clean air that flows within the IT or Server room. Common contaminants such as electrostatic

dust can affect servers, resulting in data loss and resets.

The Fluke 985 Portable Particle Counter assess air quality easily and accurately by providing an the particle size counts within the area.

Versiv™ CableAnalyzer™

Fluke Networks Versiv™ copper and fiber CableAnalyzer ™ will test and certify network cabling to stringent international standards like TIA-568 and ISO 11801, to ensure networks services will run at the desired Ethernet speed.

Certify the performance of MPO trunks for loss and polarity

MultiFiber Pro Optical Power Meter and Source is the first fiber tester that can certify MPO fiber trunks without the use of fan-out cords. This singlemode and multimode MPO fiber testing kit eliminates the complexity of polarity issues, and it makes cassettes easier to test in the field.

Fiber Inspection

The FI-3000 Autofocus/Autocentering Camera will inspect and certify all fiber connectors end-face to IEC 61300-3-35 test limit with automated pass/fail results in seconds. It can also integrate with Versiv™ Cabling Certification System and LinkWare™ Reporting Software for simple operation and documentation or with mobile phones for testing and sharing.

FiberLert™ Live Fiber Detector

Quickly verify fiber activity, polarity, and connectivity with the FiberLert™ Live Fiber Detector. This pocket-sized tool tests single-mode, multimode, UPC and APC patch cords and ports with a non-contact / non-contaminating detector. The LightBeat™ feature flashes the LED, indicating a powered-on condition and good battery, a timer shuts FiberLert™ off after five minutes of inactivity to extend battery life (2xAAA, included).

Fiber Optic Cleaning Kits

Dirt, dust and other contaminants are the enemies of high-speed data transmission over optical fiber. Fluke Networks' Fiber Optic Cleaning Kits are lint-free and enable an optimal wet and dry cleaning process with easy-to-use quick clean cleaners, cleaning cube/card and the best optic solvent pen to clean both patch cords and fiber end faces inside ports.

Explore the complete maintenance solutions for Data Center. Contact a local Fluke expert now.

Facilities Management (Power)

Facilities Management (Cooling)

IT/Server Room/Cabling Infrastructure