-

Power GenerationThe process of generating electric power from sources of primary energy. For utilities in the electric power industry, it is the stage prior to its delivery to end users or its storage.More

Power GenerationThe process of generating electric power from sources of primary energy. For utilities in the electric power industry, it is the stage prior to its delivery to end users or its storage.More -

TransmissionPower transmission is the movement of energy from its place of generation to a location where it is applied to perform useful work. Power is defined formally as units of energy per unit timeMore

TransmissionPower transmission is the movement of energy from its place of generation to a location where it is applied to perform useful work. Power is defined formally as units of energy per unit timeMore -

DistributionElectric power distribution is the final stage in the delivery of electric power; it carries electricity from the transmission system to individual consumers.More

DistributionElectric power distribution is the final stage in the delivery of electric power; it carries electricity from the transmission system to individual consumers.More

New Fluke 1777 Power Quality Analyzer

It’s a fact that poor power quality can have a big impact on the bottom line of power generation system. The new Fluke power quality analyzer enables you to simplify power quality logging, troubleshooting, and analysis for energy or load studies. Fast and easy setup to comply with IEEE519 power quality standards without missing out on any steps. Never miss a single transient with the fast-transient capturing rate of up to 20MS/s.

Fluke ii910 Precision Acoustic Imager

Partial discharge is a serious issue that team inspect everyday. It can lead to blackouts, fires, explosions, arc flashes. Insulators, transformers and switchgears are all potential risk areas in a power plant. In addition, leaks such as in the condenser reduces the pressure gradient between the steam exhaust to the condenser, reducing the thermal efficiency of the process. Use the Fluke ii910 to detect and locate partial discharge and compressed air/gas leakages.

Fluke BT521 Battery Analyzer

To prevent downtime during a blackout, it is critical to regularly perform maintenance on backup battery. Fluke BT521 analyze battery health condition in accordance to IEEE standard. Maintenance engineers can run tests on internal battery resistance, dc and ac voltage, dc and ac current, ripple, voltage, frequency and temperature quickly and easily.

Fluke Ti480PRO Infrared Camera

Ensure safe operation of your switchgear, transformers and backup batteries with the professional grade Fluke Ti480 PRO. Suitable for frontline maintenance team to identify signs of abnormality due to electrical faults.

Fluke 190-504-III-S Portable Oscilloscope

Power plant maintenance requires quick diagnosis on common automation and process controls that drives power plants, fine-tune PLC setup, fix motor-drive problems, and determine optimal backup battery transfer-time. The Fluke 190-504-III-S ScopeMeter enables you to conduct electrical signals troubleshooting from microelectronics to electrical motor systems easily with the autoview setup. The fast sampling of to 5.0 GS/s captures troubled elusive electrical signs and the recording mode allows for review of bad past events.

Fluke 1625-2 GEO Earth Ground Tester Kit

It is important to capture and maintain the value of grounding system in power generation to less than 5 ohms. To ensure a reliable contact between the electrical system and the earth, there must be a minimum impedance for the ground electrode. Fluke 1625-2 Kit lets you perform earth ground testing with selective and stakeless methods. It creates a complete maintenance report based on ISO and NFPA standard.

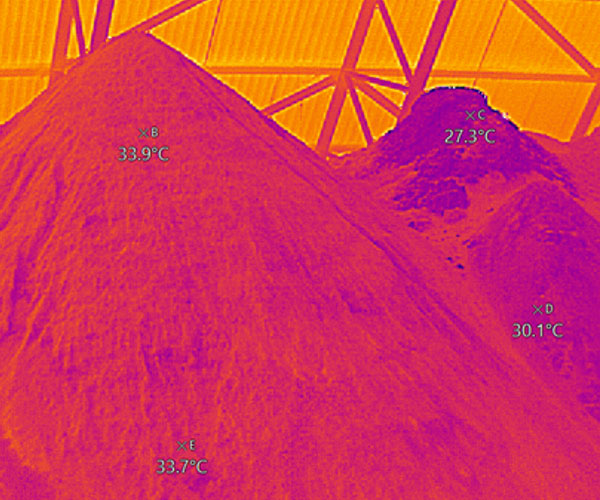

Hotspot Monitoring

Continuous monitoring of storage areas & conveyors transporting coal and bagasse used for combustion in boilers is an important step in understanding the conditions leading to a fire. Hot spots can flare-up devastating spontaneous combustion, potentially causing thousands of dollars in material loss, dangerous work conditions, and difficult extinguishing options. Prevention is becoming readily available with cost-effective continuous thermal image monitoring as a method for early warning.

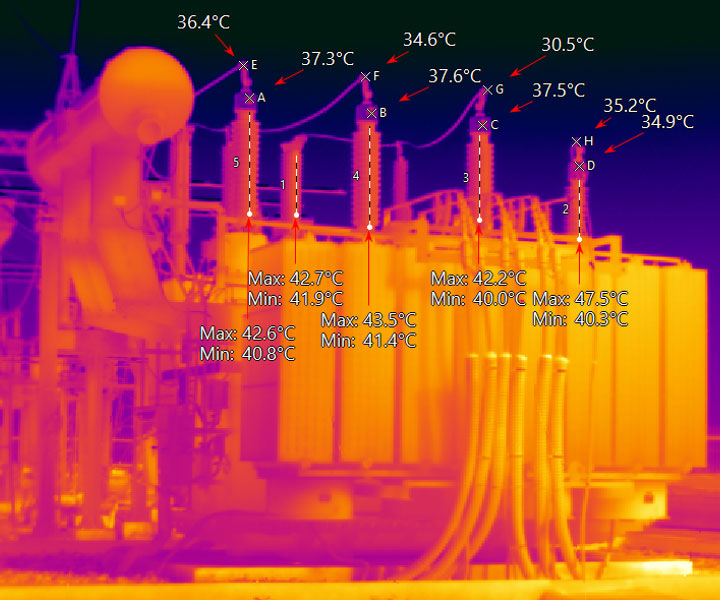

Critical Asset Monitoring

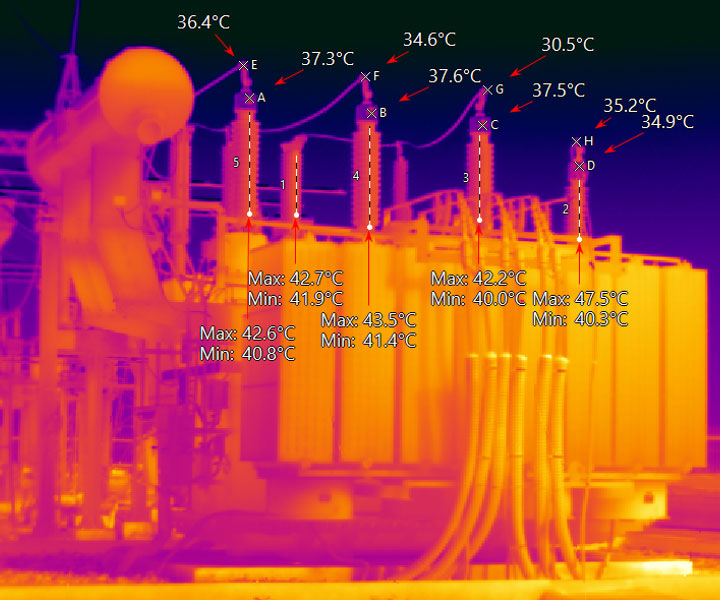

Maintaining the power distribution infrastructure is crucial to our daily survival. If critical equipment breaks down, you run the risk of disrupting the grid. The robust ThermoView TV40 & TV30 Online Thermal Imager serves as the foundation for the Critical Asset Monitoring System, which also incorporates advanced software capabilities and housing accessories made expressly for online temperature monitoring, alarming & reporting in substations and electric utility applications.

Online Continuous Thermal Monitoring

of Battery Room

Internal faults or external damage can result in battery fires. An overheated battery could release toxic gases and releases the risk of explosion. Moreover, battery fires are extremely hard to extinguish. Continuous monitoring of battery surface temperature detects temperature exceptions and protects them from overheating.

Busbar Temperature Measurement

Continuous monitoring of the busbar within a switchgear cabinet can provide both instantaneous alarms for fault conditions and trend analysis for predictive maintenance. Predictive maintenance is a most effective tool to prolong the life and efficiency of the equipment and to minimize shutdowns. A trend detected during continuous monitoring will allow for maintenance of the equipment at your choosing to minimize downtime.

Localization of Partial Discharge

Teams need to keep a close eye on partial discharge before it becomes a major problem. Online monitoring of partial discharge helps identify issues early and accurately while continuously scanning insulators, transformers, switch gears, or high-voltage powerlines. Unchecked partial discharge can result in explosions, fires, blackouts, or fatal arc flashes. This has a very high cost in addition to the potential harm it can do to people's health and the environment.

Fluke 810 Vibration Tester

Mechanical issues in pumps, gearbox and motors for cooling tower can lead to downtime for power facilities, resulting in expensive operational costs. The Fluke 810 increase maintenance team's capability to automatically diagnose the common mechanical faults and fix the root causes without having to call in specialists.

Fluke 831 Shaft Alignment Tool

Misalignment causes at least half of all damage to rotating machinery. Laser alignment can serve as a fast and easy solution. The fluke 831 provides adaptive alignment capabilities that uses precise and actionable answers to correct any misalignment in read-time.

Fluke Ti480 PRO Infrared Camera

Motor and drive is the most important equipment in power generation process line. It needs to be maintained and monitored to prevent downtime. When the motor connects to a high load system or in the event of a bearing failure, the motor will overheat and damage the winding insulation. Thermography is used to identify inefficiency in mechanical systems to achieve optimum operating and energy usage condition. With the Fluke Ti480 PRO, maintenance team will be able to detect bearing problems and insulation failure before the motor breakdown. This can reduce the maintenance cost for facility teams.

Fluke 754 Documenting Process Calibrator

Gone are the days where you may face shortage of labour resources, or required to handle multiple tasks with less time. The All-in-One Fluke 754 Documenting Process Calibrator comes with less tools and wide capabilities. It offers HART support, source and measure capabilities to manage temperature, pressure, and electrical loop all in one single trip. It is designed to be used both in the field or lab for routine calibration, maintenance and troubleshooting typical in the power plants.

Fluke 729 Pro Automatic Pressure Calibrator

Pressure control devices play a significant role to ensure safe presssure regulation and deliver feedback when unsafe pressure level is met. It has been a challenge to obtain quality pressure test results. The Fluke 729 Pro Automatic Pressure Calibrator streamlines the pressure testing up to 1,000psi while delivering accurate results. The automated pressure testing workflow from pressure generation to documentation increases the task efficiency and achieves consistent quality. It is applied on any pressure instrumentation - transmitters, switches, gauges.

Fluke ii910 Precision Acoustic Imager

Even the smallest air leaks can result in huge energy waste and loss of production time in a power generation facility. By using the Fluke ii910, maintenance team can easily identify leakages. The Fluke ii910’s array of super sensitive microphones detects sounds both in the human hearing range and the ultrasonic range and even more uniquely, allows the user to actually see sound. Air leaks can cause compressed air-driven equipment to work harder, leading to wasted energy. The potential for air leaks in the plant is further increased by the presence of older equipment accumulated over the last few decades from various plant consolidation. Now with Fluke ii910, you can see the leak you can't hear.

Fluke Ti480PRO Thermal Imager

Many power generation facilities rely on furnaces, boilers, and chiller system for manufacturing processes. These systems are prone to failures such as slag build-up on the outside of tubes, clinker damage, under and overheating, flame impingement on tubes due to burner misalignment, and product leaks that ignite and cause serious damage to the equipment. These failures cause not only quality problems; they can also shut down an entire process line. Fluke Ti480 PRO can detect most of these equipment problems during operation, and at an early stage so failures can be prevented. This allows an orderly shutdown and component replacement, thereby reducing maintenance costs and production losses.

Furnace Exit Gas Temp Measurement System

The furnace exit gas temperature in a utility boiler is one of the key parameters which imparts information about boiler performance and safety. As a result, it’s crucial to monitor this parameter not only during continuous operation but also during a boiler startup. This Thermalert T40 gas sensors coupled with robust accessories is an ideal solution for FEGT measurement in boilers & incinerators.

Fluke Calibration 9142 Field Metrology Well

These industrial temperature loop calibrators are perfect for performing transmitter loop calibrations, comparison calibrations, or simple checks of thermocouple sensors. With the “process” option, there is no need to carry additional tools into the field. This optional built-in two-channel readout reads resistance, voltage, and 4–20 mA current with 24 volt loop power. It also has on-board automation and documentation. Combined, the three models (9142, 9143, and 9144—each with a “process” option) cover the wide range of –25 °C to 660 °C.

Fluke Calibration 1524 Handheld

Thermometer Readout

The 1524 uses current reversal, a technique used in high-end instruments that eliminates thermal EMFs, for precision temperature measurements. Specifications are guaranteed from -10 °C to 60 °C ambient. Special precision resistors and a highly stable reference voltage source keep 1524 accuracy virtually insensitive to environmental temperature.

Fluke Ti480 PRO Thermal Camera + IR Window

For electricians doing electrical inspection, safety is critical. Substation maintenance involves very high voltage that can be dangerous. Use the high resolution 640 x480 Fluke Ti480 PRO to easily carry out measurements from a safe distance. The Infrared Window can be installed at the panel door to reduce the risk of arc flahes. Key areas to inspect are electrical panels, transformer cooling systems, circuit breakers, bushings etc.

New Fluke 1777 Power Quality Analyzer + PQ window

Fluke 1777 provides the record data that includes measurement methods, time aggregation, accuracy and evaluation for each power quality parameter to obtain reliable, repeatable and comparable results. In a distribution site, Fluke 1777 is ideal to monitor dips, swells, inrush current and harmonics. It is also capable of transient capturing at to 20MS/s up to 8kV. Coupled with the PQ Window, enable connection of three phase measurement equipment to energized panels without the need to open the panel door, or wear supplemental personal protective equipment (PPE).

Fluke BT521 Battery Analyzer

In the event of a power failure or outage, having reliable DC system batteries is critical. Perform regular battery maintenance in line with IEEE1188 standard to increase battery lifespan and prevent failure. FLuke BT521 captures internal resistance to identify the battery health.

Fluke 1625-2 Earth Ground Tester

Routine grounding testing for distribution building and transfomer grounding is important. As time passes, connections or bonds can loosen, wrong materials used to form initial connection can fail and corrosion can damage connectors and ground rods. Fluke 1625-2 provides the complete grounding testing without having to remove the ground electrode. AFC (Automatic Frequency Control) can identify existing interference and choose a measurement frequency to minimize its effect, thus providing a more accurate earth ground value.

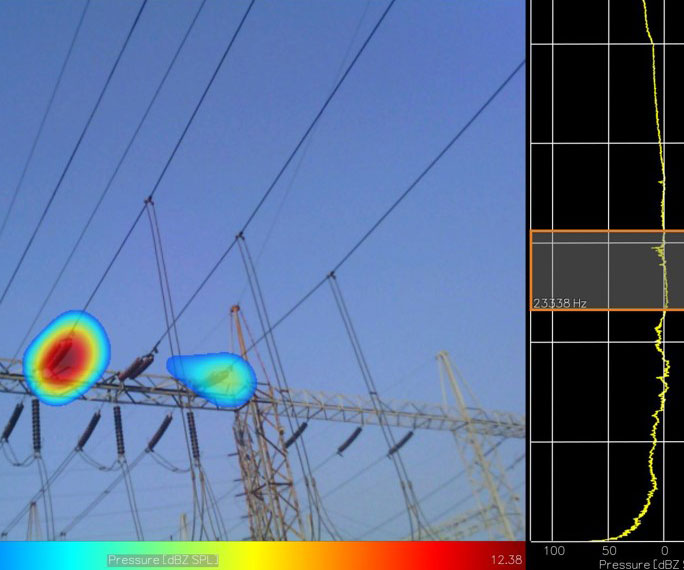

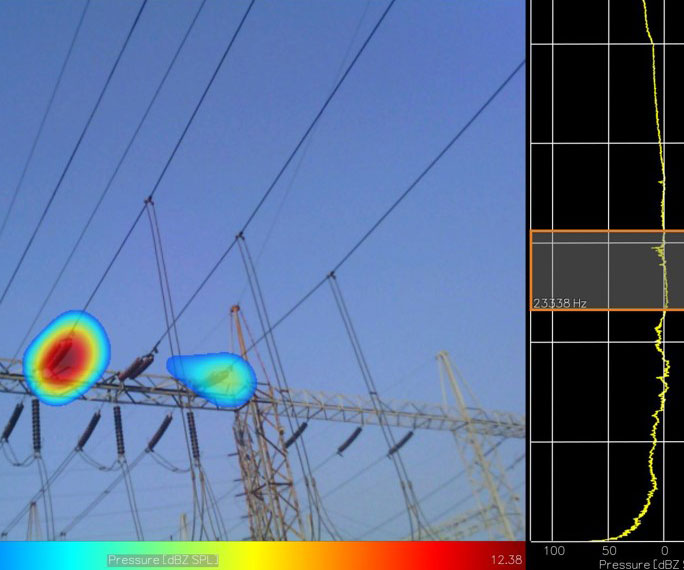

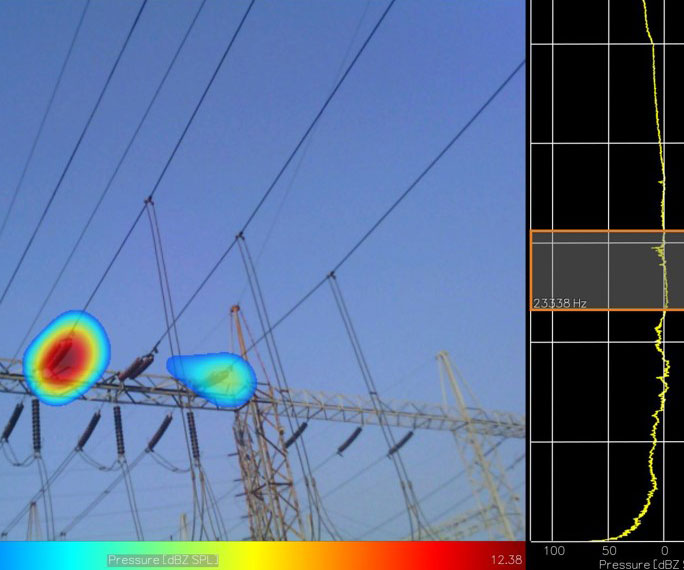

Fluke ii910 Precision Acoustic Imager

Partial discharge is a serious issue that teams monitor everyday. Whether you are scanning insulators, transformers, switch gears or high voltage powerlines you need to be sure that you spot a problem quickly and early. Partial discharge that goes unchecked can cause blackouts, fires, explosions, or death from arc flashes. In addition to the danger that this can pose to the environment and human lives, it also has a very steep price tag. Use the Fluke ii910 to detect early symptoms of PD.

Fluke 125B Industrial ScopMeter

Waveform visual display function has been an integral part of electrical maintenance. This valuable information reveals hidden signs of problem such as electrical stability and distortion before catastrophic failure occurs. Use Fluke 125B to perform critical check on electrical systems, backup battery systems, UPS transfer time and troubleshooting.

Amprobe UAT-620 Underground Utilities Locator Kit

Underground cable fault is a challenge to identify without the right tool. The UAT-620 locator kit and A-frame cable fault locator comes with the required tools to identify the location of metallic, sewer pipes, energized or de-energized HV cables underground. Both active and passive modes are built-in to support different environmental conditions.

Online Continuous Thermal Monitoring

of Battery Room

Internal faults or external damage can result in battery fires. An overheated battery could release toxic gases and releases the risk of explosion. Moreover, battery fires are extremely hard to extinguish. Continuous monitoring of battery surface temperature detects temperature exceptions and protects them from overheating.

Busbar Temperature Measurement

Continuous monitoring of the busbar within a switchgear cabinet can provide both instantaneous alarms for fault conditions and trend analysis for predictive maintenance. Predictive maintenance is a most effective tool to prolong the life and efficiency of the equipment and to minimize shutdowns. A trend detected during continuous monitoring will allow for maintenance of the equipment at your choosing to minimize downtime.

Localization of Partial Discharge

Teams need to keep a close eye on partial discharge before it becomes a major problem. Online monitoring of partial discharge helps identify issues early and accurately while continuously scanning insulators, transformers, switch gears, or high-voltage powerlines. Unchecked partial discharge can result in explosions, fires, blackouts, or fatal arc flashes. This has a very high cost in addition to the potential harm it can do to people's health and the environment.

Fluke ii910 Precision Acoustic Imager

High voltage powerlines are exposed to the risk of partial discharges. The Fluke ii910 uses groundbreaking acoustic technology to overcome the laborious task of locating invisible threat. Easily detect and identify partial discharge from up to 120m away.

Fluke TIX580 + smart lens

Heat is often an early symptom of equipment damage making it a key parameter to monitor for predictive maintenance. The Tix580 expert series articulated camera is highly suited for outdoor utility inspection. Achieve better spatial resolution through optical zoom with the interchangeable 2x and 4x telephoto lenses.

Fluke 1625-2 Earth Ground Tester with Split Core Transformer

Transmission towers are solidly earthed at the base either directly by the buried leg structure or more commonly via a radial earthing strip. All these factors can contribute to a deterioration in the effective earthing of the transmission line and its ability to dissipate lightning strikes. Measuring the earth resistance of a tower in-service without disconnecting the overhead earth wire is achieved with the injection of an off-mains-frequency test current into the tower structure. The test current will flow to ground via the tower legs and the earth straps, but a significant proportion will escape via the overhead earth wire and flow to ground via all other towers and the switchyard grids. If the component of current flowing to earth via the legs and the earth straps is measured, the earth resistance of the individual tower can be calculated using Fluke 1625-2 with split core transfomer.

Amprobe TIC 300 PRO High Voltage Detector

MSHA certified and intrinsically safe, the Amprobe TIC 300 PRO High Voltage Detector with VolTect™ alert is a rugged, reliable, non-contact, high voltage tester for utility, industrial, and mine safety applications up to 122kV. Voltage detectors are used to check for the absence or presence of voltage on medium and high switchgear, transformers or overhead lines – electrical safety is imperative in all areas of power transmission and distribution at all voltage levels including MV, HV and EHV up to 122kV. If the power system is Live then a visual and audible signal will be heard and seen from the detector.

New Fluke 1777 Power Quality Analyzer

Harmonic direction is one of the critical measurements to be conducted regularly at the substation for engineers to understand the harmonic impact and direction. Fluke 1777 complies with IEC61000-4-30 class A standard to provide the highest performance and accuracy when it comes to power quality event capturing. Get fast transient capturing up to 20MS/s.

Fluke 1625-2 Earth Ground Tester

The vast majority of power substation systems are designed so that, if an insulation failure or similar fault occurs, the resulting fault current is diverted to earth. This prevents exposed conductive parts from rising to a dangerous potential, while allowing the fault current to flow for long enough and at a high enough level for protective devices to operate and isolate the fault. It is clear from this description that a reliable, effective earth connection is essential for safe operation of the systems, and that if the earthing system fails or becomes inefficient, at best safety will be compromised and at worst there may well be a significant risk to life and property. Use the Fluke 1625-2 to capture earth resistance value for predictive solution.

Fluke BT521 Battery Analyzer

To help ensure reliability, stationary batteries need to be maintained and tested regularly. Even "maintenance free" batteries require regular testing because they can deteriorate over time. All it takes is one battery in the string to fail to take the entire string off-line. One bad battery will affect the usable life of adjacent batteries by raising their charge voltage. Worse still, a battery or interconnect with a high impedance could overheat, ignite, or explode during a discharge. Fluke BT521 can test battery performance without disconnnecting the battery from the system.

Fluke TIX580 + smart lens

Heat is often an early symptom of equipment damage making it a key parameter to monitor for predictive maintenance. The Tix580 expert series articulated camera is highly suited for outdoor utility inspection. Achieve better spatial resolution through optical zoom with the interchangeable 2x and 4x telephoto lenses.

Fluke 1555 (10kV) Insulation Tester

Insulation testing is used to ensure all current in a cabled system travels properly through the conductor to other parts of the circuit, as well as to maintain the safety and integrity of the electrical network. Electrical stress involves the trio of corona, surges, and partial discharges. Use the Fluke 1555(10KV) to identify insulation for HV cable.

Fluke 125B Portable Oscilloscope

The ScopeMeter is a handheld portable oscilloscope useful for diverse electrical measurements. The waveform visual display is useful for ensuring the signal integrity and it provides early indication of problem build-up before catastrophic failure occurs. Apply it to critical check on backup battery systems to determine health of the rectifier systems and UPS transfer time.

UAT-620 Underground Utilities Locator Kit

It is essential to find out if the location has underground utility line before constructing new transmission sites. The UAT-620 locator kit comes with the required tools to identify the location of metallic, sewer pipes, energized or de-energized cables underground. It comes with various tracing modes to handle different conditions.

Critical Asset Monitoring

Maintaining the power distribution infrastructure is crucial to our daily survival. If critical equipment breaks down, you run the risk of disrupting the grid. The robust ThermoView TV40 & TV30 Online Thermal Imager serves as the foundation for the Critical Asset Monitoring System, which also incorporates advanced software capabilities and housing accessories made expressly for online temperature monitoring, alarming & reporting in substations and electric utility applications.

Online Continuous Thermal Monitoring

of Battery Room

Internal faults or external damage can result in battery fires. An overheated battery could release toxic gases and releases the risk of explosion. Moreover, battery fires are extremely hard to extinguish. Continuous monitoring of battery surface temperature detects temperature exceptions and protects them from overheating.

Busbar Temperature Measurement

Continuous monitoring of the busbar within a switchgear cabinet can provide both instantaneous alarms for fault conditions and trend analysis for predictive maintenance. Predictive maintenance is a most effective tool to prolong the life and efficiency of the equipment and to minimize shutdowns. A trend detected during continuous monitoring will allow for maintenance of the equipment at your choosing to minimize downtime.

Localization of Partial Discharge

Teams need to keep a close eye on partial discharge before it becomes a major problem. Online monitoring of partial discharge helps identify issues early and accurately while continuously scanning insulators, transformers, switch gears, or high-voltage powerlines. Unchecked partial discharge can result in explosions, fires, blackouts, or fatal arc flashes. This has a very high cost in addition to the potential harm it can do to people's health and the environment.